Textile Environmental Testing

Textiles are composed of different fibers arranged in a variety of ways to create the durability, strength, appearance, and texture expected of a fabric. Fibers include natural, vegetable, animal, man-made and synthetic. After preparing the fibers, the next step in the process is spinning the fibers into yarn. Next is fabric production. Fabrics can be manufactured in many different ways; the most common are woven, knitted or produced through nonwovens. During this step, the yarn must be strengthened so that it does not break during the process. After fabric production, pretreatment is required to accept dyes and functional chemicals in the fabric. Once the pretreatment is complete, the fabric is ready for dyeing and printing. After this step is finishing, which varies according to the intent of the fabric. Some examples of desired properties are flame retardancy, water resistance, antimicrobial treatment and protective coatings.

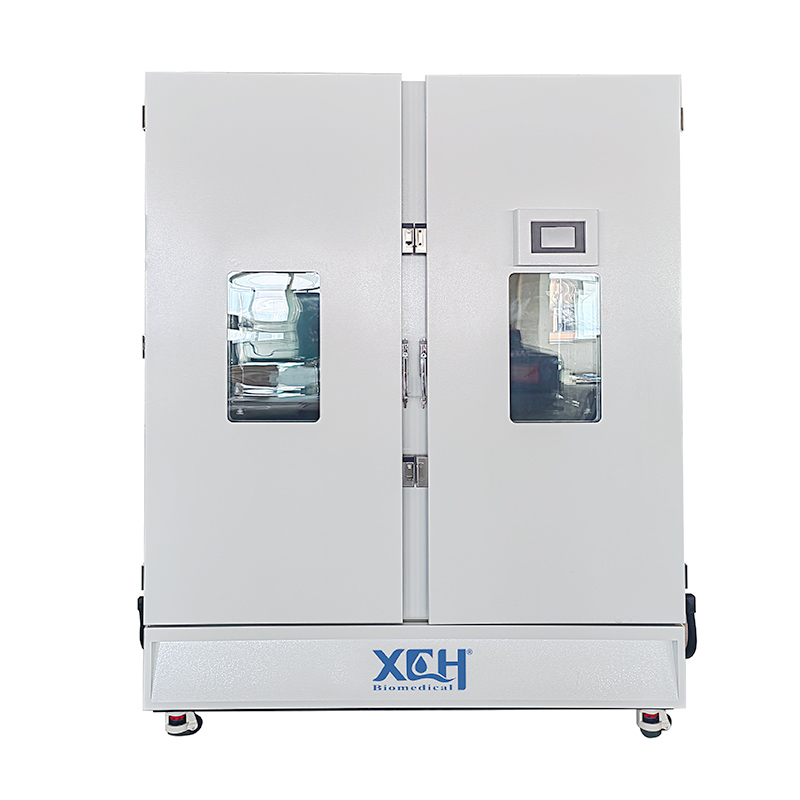

To ensure the reliability of textile products over time, XCH Biomedical manufactures steady state chambers and chambers. These devices are designed for testing accelerated burn-in, burn-in, and controlled temperature storage. The test chamber itself is available in a variety of configurations to best suit your needs.

English

English Français

Français Deutsch

Deutsch Русский

Русский Español

Español Português

Português عربي

عربي 日语

日语 한국인

한국인 Melayu

Melayu Tiếng Việt

Tiếng Việt Indonesia

Indonesia বাংলা

বাংলা 中文

中文

IPv6 network supported

IPv6 network supported